Manual Hand Pumps for Wells

Manual hand pumps are a reliable and sustainable way to access water from wells, especially in areas without access to electricity or where power outages are frequent. These pumps utilize human power and mechanical advantage to draw water from the well, making them a practical solution for both residential and agricultural purposes.

Introduction

Manual hand pumps for wells have been a cornerstone of water extraction for centuries, providing a reliable and sustainable solution for accessing groundwater. These pumps, powered by human strength, offer a practical alternative to electrically powered pumps, particularly in areas where electricity is unavailable or unreliable. The simplicity and durability of manual hand pumps make them a valuable asset in various scenarios, including remote locations, emergency situations, and even as a backup source for homes with electric well pumps.

The use of manual hand pumps is not limited to rural areas. They can be found in urban settings as well, particularly in older neighborhoods where wells were once common. These pumps often serve as a backup source for water in case of power outages or as a supplemental source for watering gardens or filling livestock troughs. Their ability to function without electricity makes them highly valuable in situations where power grids are unreliable or nonexistent.

The working principle of manual hand pumps is based on the creation of negative pressure, which draws water up from the well. The pump lever or handle is connected to a piston or diaphragm that moves up and down within a cylinder. As the handle is pumped, the piston or diaphragm creates a vacuum within the cylinder, drawing water up from the well through a pipe. The water is then discharged through a spout or nozzle, allowing users to access fresh water.

Manual hand pumps come in various designs and materials, each tailored to specific applications and well depths. Some pumps are designed for shallow wells, while others are capable of drawing water from depths exceeding 100 feet. The choice of pump depends on factors such as the well depth, the volume of water required, and the desired flow rate.

In today’s world, manual hand pumps continue to play a significant role in providing access to clean water. They are an essential tool for communities and individuals in areas with limited access to electricity or in situations where a reliable source of water is crucial.

Types of Manual Hand Pumps

Manual hand pumps for wells are available in a variety of designs, each catering to specific well depths, water requirements, and user preferences. Understanding the different types of pumps helps in selecting the most suitable option for a particular application. Here are some common types of manual hand pumps⁚

Piston Pumps⁚ These pumps employ a piston that moves up and down within a cylinder, creating a vacuum that draws water up from the well. Piston pumps are typically used for shallow wells and are known for their simplicity and durability. They are often found in older wells and are a reliable choice for basic water extraction.

Diaphragm Pumps⁚ Diaphragm pumps utilize a flexible diaphragm that moves up and down within a chamber, creating a vacuum to draw water up. These pumps are generally more efficient than piston pumps and are often used for deeper wells. Diaphragm pumps are also known for their ability to handle small amounts of sediment or debris in the water.

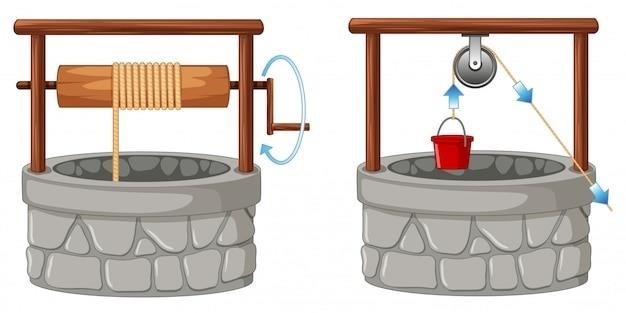

Rotary Pumps⁚ Rotary pumps use a rotating impeller to draw water up from the well; These pumps are typically more complex than piston or diaphragm pumps and are often used in commercial or industrial applications. Rotary pumps are known for their high flow rates and ability to handle larger volumes of water.

Hand-Operated Submersible Pumps⁚ These pumps are designed to be submerged in the well and are often used for deep wells. The pump is connected to a hand crank or lever on the surface, which operates the pump motor. Submersible pumps are typically more efficient than surface pumps and are able to handle larger volumes of water.

Simple Pumps⁚ These are a relatively new type of hand pump that is designed for ease of use and installation. They often feature a simple design and are typically used for shallower wells. Simple pumps are known for their lightweight design and reduced pumping effort, making them a popular choice for residential applications.

The choice of pump type depends on factors such as the well depth, the volume of water required, the desired flow rate, and the specific requirements of the application. Consulting with a qualified well pump specialist can help determine the best type of manual hand pump for a particular well.

Working Principle of a Manual Hand Pump

Manual hand pumps operate on a simple yet effective principle that utilizes the power of human effort to move water from a well to the surface. The core mechanism involves creating a vacuum within the pump cylinder, which draws water up from the well. This vacuum is typically generated by a piston, diaphragm, or rotary impeller, depending on the type of pump.

Let’s break down the working principle of a typical piston pump as an example. The pump consists of a cylinder with a piston that moves up and down within it. When the piston is pulled up, it creates a vacuum in the cylinder. This vacuum draws water up from the well through a suction pipe, which is connected to the bottom of the cylinder. As the piston moves down, it pushes the water up through a discharge pipe, which delivers the water to the surface.

Diaphragm pumps function similarly but utilize a flexible diaphragm instead of a piston. The diaphragm moves up and down, creating a vacuum that draws water up from the well. Rotary pumps use a rotating impeller to create a centrifugal force that pushes water up the discharge pipe.

The efficiency of a manual hand pump depends on several factors, including the depth of the well, the size of the pump cylinder, and the effort applied by the user. The deeper the well, the more effort is required to pump water to the surface. Larger pump cylinders can handle greater volumes of water, but they also require more effort to operate.

Understanding the working principle of a manual hand pump provides valuable insights into its operation and limitations, aiding in choosing the right pump for a specific well and ensuring its effective use.

Advantages of Manual Hand Pumps

Manual hand pumps offer a range of advantages that make them a valuable option for water access in various situations. Their primary strength lies in their independence from external power sources, making them a reliable solution in remote areas or during power outages. This independence translates into cost savings as there are no electricity bills to worry about.

Furthermore, manual hand pumps are known for their simplicity and ease of maintenance. Their mechanical design is relatively straightforward, making them less prone to complex breakdowns. Regular cleaning and lubrication are generally sufficient to ensure their continued operation. The absence of intricate electronics or moving parts also contributes to their longevity, often lasting for decades with proper care.

Another significant advantage is their environmental friendliness. Manual hand pumps operate without relying on fossil fuels or generating emissions, contributing to a cleaner and more sustainable water access system. This is particularly important in regions where water resources are already under pressure and environmental concerns are paramount.

In addition, the manual operation provides a direct connection to the water source, allowing users to control the flow rate and volume of water extracted. This control can be beneficial in managing water consumption and preventing waste. Moreover, the physical effort required to operate the pump can provide a form of exercise, promoting a healthy lifestyle.

Overall, the advantages of manual hand pumps make them a compelling choice for water access in diverse settings, offering a reliable, cost-effective, and environmentally responsible solution.

Disadvantages of Manual Hand Pumps

While manual hand pumps offer several advantages, they also come with certain disadvantages that need to be considered. The most significant drawback is the physical effort required to operate them. Pumping water manually can be strenuous and time-consuming, especially when drawing water from deep wells or when a large volume of water is needed. This physical exertion can be a challenge for individuals with limited physical strength or mobility, limiting their access to water.

Another disadvantage is the limited flow rate. Manual hand pumps generally produce a lower water flow compared to electric pumps, which can be a constraint for applications requiring a continuous and high-volume water supply. This lower flow rate can also make it challenging to use the pump for tasks requiring a steady stream of water, such as irrigation or filling large containers quickly.

The depth of the well can also be a limiting factor. While some hand pumps are designed for deep wells, their effectiveness decreases with increasing depth. The physical effort required to pump water from deep wells becomes more challenging, and the volume of water extracted may be reduced. This limitation restricts the use of hand pumps in areas with very deep wells.

In addition, the maintenance of manual hand pumps can be more demanding than electric pumps, requiring regular cleaning, lubrication, and potential repairs. The moving parts are susceptible to wear and tear, especially with frequent use, requiring attention to ensure their continued operation.

Overall, while manual hand pumps offer a valuable alternative for water access, their disadvantages, primarily the physical effort and limited flow rate, need to be weighed against their advantages before making a decision.

Installation and Maintenance

Installing a manual hand pump requires careful consideration and proper execution to ensure its efficient and reliable operation. The installation process typically involves connecting the pump to the well casing, ensuring a secure and leak-proof connection. This may involve using specialized fittings and sealing materials to prevent water leakage and maintain the integrity of the system.

Once installed, regular maintenance is crucial for the longevity and optimal performance of the hand pump. This includes periodic cleaning of the pump components to remove any debris or sediment that may accumulate over time. Lubricating moving parts, such as the piston and connecting rods, is essential to reduce friction and prevent wear and tear.

Checking the pump’s operation and addressing any issues promptly is vital. This may involve inspecting the pump for leaks, verifying the smooth operation of the piston, and ensuring proper sealing of the well casing. Addressing any problems early can prevent more significant issues from arising and ensure the pump’s continued functionality.

In addition to routine maintenance, it’s crucial to protect the hand pump from harsh weather conditions. This may involve providing a protective cover or enclosure to shield the pump from rain, snow, or extreme temperatures. Regularly inspecting the pump’s condition and addressing any signs of damage or deterioration is essential for its long-term performance.

Proper installation and regular maintenance practices are crucial for maximizing the lifespan and efficiency of manual hand pumps, ensuring their reliable and sustainable operation for accessing water from wells.

Applications of Manual Hand Pumps

Manual hand pumps find diverse applications in various settings, particularly where access to electricity is limited or unreliable. Their ability to provide a consistent water supply without external power sources makes them suitable for a wide range of purposes.

In rural communities, manual hand pumps are a vital source of clean drinking water. Their ease of installation and operation makes them an accessible option for households, schools, and community centers. In areas prone to power outages, hand pumps offer a reliable backup water source, ensuring access to clean water even during emergencies.

Beyond domestic use, manual hand pumps play a significant role in agricultural practices. They provide water for irrigation, livestock, and other agricultural needs, supporting sustainable farming methods, especially in regions where water resources are scarce.

Furthermore, hand pumps find application in disaster relief efforts, providing essential water access in emergency situations. Their portability and ability to function without external power make them ideal for delivering water to affected communities following natural disasters or humanitarian crises.

In remote locations, manual hand pumps are often the most practical and cost-effective solution for water access. Their simplicity and low maintenance requirements make them a sustainable option for communities without access to modern infrastructure.